RAM Iron & Metal is building on growth and ready for the challenges ahead

Ontario scrap recycler remains focused on its customers and people, sustainable operations and adaptability

By Keith Barker February 11, 2021

Andy Racco and Frank Ruffolo at Ram Iron & Metal in Ontario, in front of their Harris shear-top ferrous baler and Liebherr material handler with magnet grapple.

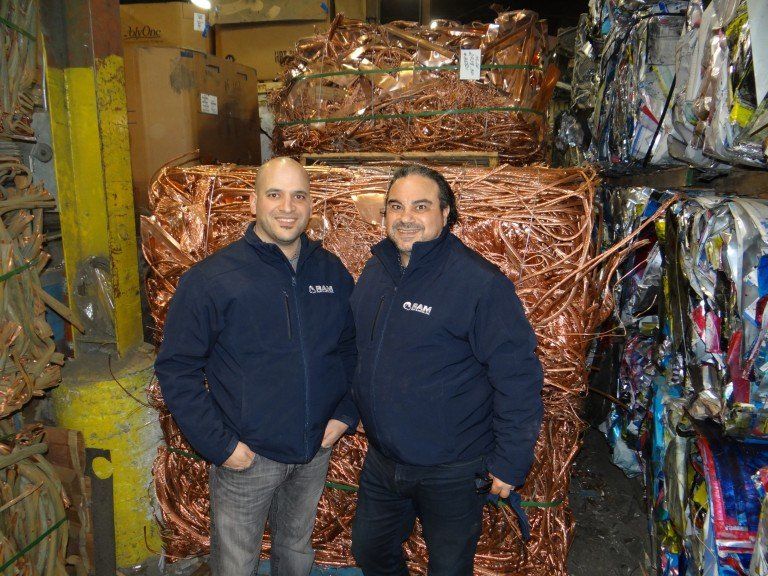

Ram Iron & Metal’s co-owner Andy Racco, with sales and marketing manager, Frank Ruffolo.

Customer-Obsessed Success

According to Frank Ruffolo, RAM Iron & Metal’s sales and marketing director, “We are customer-obsessed. We want to provide exceptional customer satisfaction, highlighted by the way our partnerships continue to grow, and we have attained high service level grades. Our Google rating is 4.6 stars, which is among the highest in the industry.”

Both Racco and Ruffolo emphasize that RAM Iron & Metal’s success is really driven by the fact that they maintain a continuous flow of material into their facilities, which relies on their solid ongoing relationships with customers, whether it be an industrial or an institutional client, or a scrap dealer.

“Our company business goals are to grow organically, and in an ethical manner,” says Racco. “We like to grow with our customers and identify opportunities that make sense. We’re not out there buying up other companies to grow our market share. We’re firming up our relationships. We’re investing in our facilities and training our personnel. We’re always on top of our equipment and increasing our safety protocols as well.”

Racco explains that they maintain and grow their customer base through both education and transparency. This involves teaching their customers about the scrap metal recycling process overall.

“Straight from their waste generation all the way through to the mill or foundry, if we can help improve or streamline our customers’ process through education, we know that makes us a better partner and it provides more profits for customers. Our business is really about helping companies turn industrial recyclable material into profits.”

Ram Iron & Metal operates three yards in Ontario where they maintain a good balance between ferrous and non-ferrous capacity.

The Environmental Priority

Over the last decade, RAM Iron & Metal has remained focused on their environmental responsibilities, by reducing harmful impact and how it’s presented to their customer base.

“We’re a recycling facility,” says Ruffolo. “What that means is, it’s our responsibility to meet the needs of our industrial accounts and avoid releasing toxins into our communities.”

One of RAM’s strategies for minimizing their environmental footprint is the use of the latest technology in catch basins and fluid drainage systems for processing automotive and machinery lubricants. For ELV (end-of-life vehicle) drainage, they use two SEDA Environmental systems. All oils, fluids and drippings from processed scrap vehicles are segregated and responsibly managed.

According to Ruffolo, “Specifically, when we’re talking about protecting the environment, we’re hiring experts and collaborating with external environmental experts to continuously upgrade our practices and proficiency. We also work very closely with government to consistently test our environmental processes. It’s very important for us to be recognized for both our ISO Quality and ISO Environmental certifications, as it provides instant credibility to new potential partners. Moreover, it provides a sense of pride to our entire organization, as all employees have contributed.”

He says this is very important not only to RAM Iron & Metal as a business, but also to their customers.

“Through our ISO certifications, we were able to polish our best practices,” Racco adds. To mitigate their environmental footprint, they not only need to deal with their own facility, but educate their client base on how to reduce at the source. “The question is, how can we start decreasing the harmful fluids coming into our yard by recycling them at the source?

“It’s the education of do’s and don’ts,” he continues. “Sometimes it’s as simple as reinforcing that metal containers, such as paint and aerosol cans, cannot contain liquids when they come to us. Companies need to divert those products to the proper waste management partner. By recycling their fluids on site, it can increase their profits two-fold. If they recycle and reuse expensive lubricants at the source, there will be additional payment from mills, as the final product is cleaner and not contaminated.”

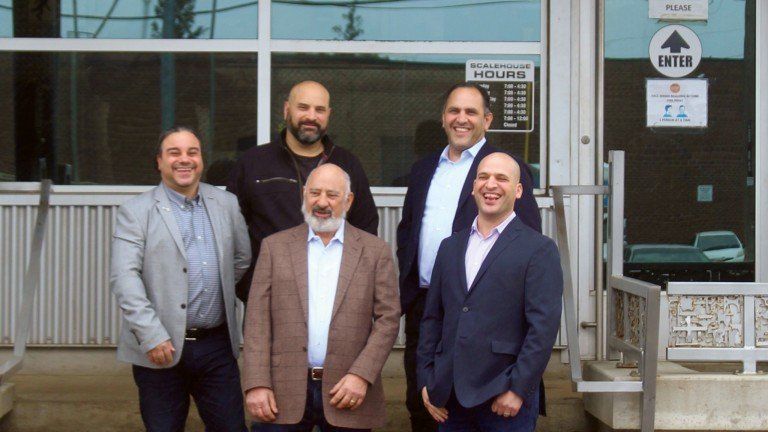

Top Row: Frank Ruffolo with Peter and Paul Racco. bottom row: Emilio and Andy Racco.

Safety and Community

A key aspect of RAM Iron & Metal’s core values is their attention to higher levels of safety in their operations.

“We’ve increased our safety network here by adding a full-time health and safety manager, who visits all three sites, throughout the day. In addition, RAM Iron & Metal continuously educates employees while reinforcing safety ideals to their partners and customers.

“Safety always comes first.” Racco says it really comes down to having the right safety policies in place. “We do our best to reduce lost days and accidents. We’ve been fortunate to avoid any serious employee accidents up to this point.”

“Right from the start, when an employee is hired, they cannot step into the workplace until they’ve passed our robust safety training. It’s an extensive protocol covering many potentially harmful situations with direction on how to act and whom to inform. There’s a reinforcement of the safety training within the first week, and then at the one- and three-month marks, and that’s just with our human resources team. Beyond this, our on-site supervisors consistently provide safety reminders during daily duties.”

With respect to community involvement, according to Racco, it’s a huge pillar of their culture. “The reason why we want to be successful is so we can give back to the community. We wholeheartedly believe in that. We donate on a regular basis to the community, from sponsoring local teams to larger charities, and we support our clients with their charity and fundraising causes.”Being a family run business, we’ve always valued community and supporting others,” he continues. “Philanthropy has always been a prominent piece of our father Emilio’s vision, and he’s made sure that we carry it forward.”

Adaptation is the name of the game

At the beginning of the global pandemic in the spring of 2020, like everybody else, Racco says they had a lot of discussion on how to handle the situation. “At the end of the day, we the leadership team had trust in our people, and we had trust that they were going to press forward and that we were going to work together to overcome challenges. We knew that we had great teams on the ground, and they are a very dedicated, resilient team. We did have to pivot toward new opportunities. We also had to work differently. With less physical contact, we had to incorporate new digital tools.”

He continues, “We increased our communication to promote more teamwork and that improved our agility. It helped us to maximize the opportunities we identified in the market. At the end of the day, we believe that it strengthened our culture and our engagement within the organization. Through everyone’s commitment and perseverance we’ve also been blessed to increase our client base, and our recycling capacity has increased. We’re very proud of these accomplishments.”

The COVID-19 pandemic has taught RAM Iron & Metal to adapt quickly. “We see a road map with obstacles and hurdles that we’ll have to overcome within our business plan. Adaptation will be the behaviour needed to successfully navigate business for the next five years.”

As for the current volatility of global export markets, Racco says it has not had a significant effect on their business as they prefer to stay domestic as much as possible. “However, we do participate in the export market to stay competitive. We feel our strength is our nimbleness to decipher the ferrous and non-ferrous categories and focus on most favourable opportunities. We follow commodity pricing trends closely and determine our strategy based on market dynamics.”

Other than their Welland, Ontario, facility enhancements in 2021, Racco says going forward their main focus will be to continue to do right by their people and clients. “This will be achieved by upskilling employee competencies, which will enable them to make smart, independent decisions that will allow RAM and our business partners to thrive.”

“As mentioned earlier, we are customer-obsessed, and we hope to continue to increase our customer satisfaction rating, thus increasing our client referrals. We believe that nothing is stronger than a current client referral to a potential partner.” RPN